Let’s say, you’re building your own remote-controlled plane or car from the scratch. For that, you definitely need a servo motor.

And you need reversed servo motors too! But for that, you have to manually reverse the servo motor.

So, how to reverse a servo?

First, we will reverse the wires which are connected to the motor. After that, reverse the wires which are on the potentiometer. Or the ones on the board. And finally, we’ll test and put everything back on. Another way is, by using a servo reverser.

Wanna know more? Here, we have explained everything about reversing servo motors.

Contents

Basics to Know Before Reversing a Servo

Now, chances are that you’re new to this. And if your RC plane is a dual elevator one, you definitely need two servos for the two halves.

But the problem is, you need 2 servos working in the opposite direction, facing each other.

You see, there are some geometrical principles you need to follow. And one of them is, the servos need to be in a symmetric position. If you mount them without reversing, they won’t meet the geometric criteria.

How in the World Does that Servo Work?

A servo motor rotates the parts of a machine with excellent precision and high efficiency. It is basically a closed-loop system.

It applies a positional feedback system in order to control the final position and motion of the output shaft. The shaft can be relocated to a certain angle, speed and position, unlike a normal motor.

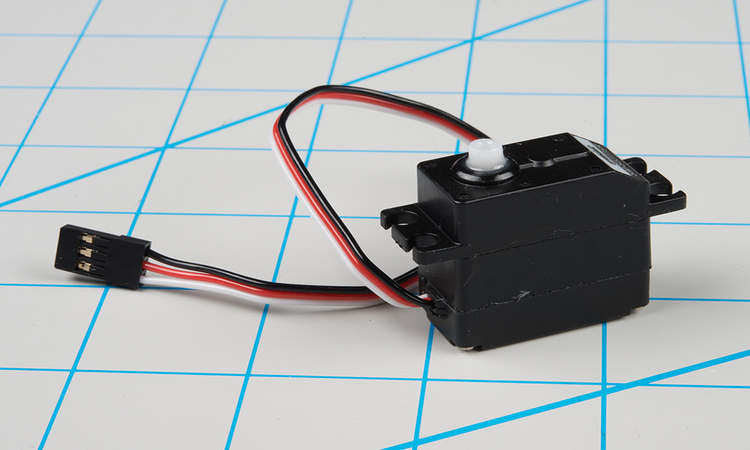

An encoder acts as a sensor that provides position and speed feedback. This whole system is built inside the servo motor along with gears, potentiometer, amplifier, shaft, control circuit, and motor.

So, what sets a servo motor apart from a regular motor? A regular motor rotates 360° continuously. It can not control angular precisions.

But a servo motor is required only when angular accuracy is necessary and its rotation is limited to 180°. Its first beat goes clockwise and then anti-clockwise and it repeats in this order.

Before starting, test your servo with a servo tester to know if it’s giving any bad signals.

Now connect your servo with the tester and see if it’s working properly. You can compare it with other servos to measure comparative performance.

Can’t We Just Flip the Servo Upside Down?

Well, this is a pretty common question that might come to your head. But the simple answer here is that it’s discouraged.

You see, our objective is to reverse the direction of the shaft. But if you mount the servo in reverse, it won’t change the shaft’s direction. You’ll be just reversing the whole body of the servo.

Think of it this way, your ceiling fan is rotating anticlockwise. Now you want it to whirl clockwise. So, you somehow set the fan upside down.

Now if you look at it from the bottom, it’s rotating clockwise. You see, it changes the perspective, not the mechanism. Which is no help to us. Get it?

Ultimately everything boils down to reversing the servo.

2 Methods of Reversing a Servo Motor

Reversing servo motor means you want the first beat to be anti-clockwise and then clockwise. You can find reverse servos in local electrical shops.

But assuming you can’t find one or you want to save money, you can easily reverse the servo motor at your home manually with nothing additional! All you need is some common household equipment.

You can reverse a servo in two ways-

Method 1: With a Servo Signal Reverser

If you don’t wanna go through all these troubles, you can simply use a servo reverser. However, you have to make room for some extra wires in this method.

On a servo signal reverser, you will see 2 cables. One is a 3-pin connector like the servo connector. Another one is a receptacle.

Now connect the servo to the receptacle of the signal reverser. And another end to the power supply. That’s it!

Applying this method is comparatively way easier and risk-free. You can remove the signal reverser whenever you want if your work is done. Or you can use it as long as you want.

But if the reverser is out of order, the servo will also stop working.

Besides that, including another device will increase the overall weight of the RC vehicle. And a bit unbalanced weight increase is bad if you’re into racing. Moreover, even in bashing, it’s important to keep a good weight distribution.

So, if you don’t want any 3rd party impact on the servo, it is better to go with method 2.

Method 2: Reversing from the Inside

Reversing from the inside means, we’ll be changing the direction from inside of the servo. When you need to reverse a single one, that is not related to other servos, you should apply this method.

Here is a list of the things that you will need for reversing your servo.

Before proceeding, make sure that you know how to handle soldering properly. The motor is a very small thing. It requires precise and expert hands in soldering. Or else it might end up doing more harm to the servo rather than solving the problem.

Now let’s dive right into business and learn how to reverse a servo motor!

Step 1 of 4: Remove the Back Cover

First of all, take out the screws from the back of the servo motor and remove the back cover.

Now you will see the motor, the board, and the potentiometer (the one that looks like a round battery) on the surface.

Step 2 of 4: Reverse the Motor Wires

The second task is to reverse the wires from the motor.

After you remove the back cover, you will see 2 wires soldered with the motor. They are usually red and black wires.

Which means one positive and one negative. If they are of different colors, don’t be worried. They work just the same. Now you have to reverse these wires.

See if the wires come out after a soft pull or not. If not, take your soldering iron and use it to separate both of them from the motor.

Make sure you’ve got a good soldering iron for total safety and precision. If you’re not sure which one to get, here are our top 3 soldering iron picks:

| Image | Title | Price |

|---|---|---|

| Soldering Iron Kit - Soldering Iron 60W | Check Price |

| Electronics Soldering Iron Kit | Check Price |

Now that you’ve got your soldering iron, solder the red wire where the black wire was previously. And the black one where the red one was.

Step 3 of 4: Reverse the Potentiometer Wires

The next step is, reverse the wires connected with the potentiometer or board.

Now, notice the 3 wires that are connecting the board with the potentiometer. Again, don’t worry about the color of the wires.

Here you have two alternatives. You can follow either of them.

Alternative 1 of 2: Reversing the Potentiometer Wires

The first one is, reverse the wires in the potentiometer.

Use your soldering iron like before and separate the 2 outer wires from the potentiometer. Remember, the outer wires; not the one in the middle. After you’ve disjointed them, swap their positions as you did earlier and fuse them with the holders.

If the available wire is not long enough to swap positions, remove the whole wire from the board as well as from the potentiometer. And then connect a new wire on that spot.

Alternative 2 of 2: Reversing the Board Wires

The second option is, to swap the outer wires from the board.

Find the 3 wires that connect the board with the potentiometer, separate the outer ones, swap them and fuse them…. that’s right, just like before!

If you are going for the second alternative, you may get confused. Because there are also other wires connected to the board that goes to the power supply.

So, it is better to go with the first option as there are only those 3 wires that are connected to the potentiometer. It is a little less puzzling.

That’s it! Now all that’s left is just testing.

Step 4 of 4: Test

Before putting the back cover on, check if it’s working correctly. For this, fetch a good quality servo tester.

It should be working fine now. If not, make sure to follow the whole process carefully and try again.

Once you’ve confirmed it, put everything as they were in the body and put the back cover on.

And there you have it! This is how to reverse a servo direction.

Precautions

Before starting, ensure these precautionary steps to avoid injuries.

- Never touch the soldering metal

- Handle the soldering iron carefully

- Don’t keep water around the motor

FAQs

Do I need to turn the motor around?

No. If you turn the motor around, then the whole mechanism will be reversed. Which will take you back to square one.

Can I reverse all types of servo motors?

Unfortunately, no. You can reverse the servo only if it is brushed. If it is brushless, this method will not apply to it.

How can I reset a servo motor?

Take the servo arm out, determine the servo position with the Arduino, and then attach the servo arm back on.

Conclusion

As mentioned earlier, the movement of the shaft depends on the signal it receives. In usual circumstances, the signal tells the shaft to first move clockwise and then anti-clockwise.

But by reversing the wires of the motor and the potentiometer, we reversed the signal too. And therefore it commands the shaft accordingly.

Now that we’re here, we hope you’re clear about how to reverse a servo. Feel free to leave your feedback in the comment section!